Menu

MEDIUM AND HIGH VOLTAGE SUB-ASSEMBLIES

SINGLE-PHASE CAPACITORS

Single-phase power capacitors are manufactured for use indoors and outdoors.

The capacitors are equipped with internal coil protections and discharge resistors that guarantee reduced voltage on terminals, in compliance with the standards.

The capacitor’s dielectric material is polypropylene in the form of coatings sprayed on both sides of an aluminium foil, encapsulated in a stainless-steel, powder coated housing.

GENERAL TECHNICAL PARAMETERS

Rated voltage: 1…30 kV

Rated power: 10…900 kVar

Frequency: 50 or 60 Hz

Active power loss: 0.07…0.15 W/kVar

Capacitance tolerance: -5% … +10%

Temperature class: -40 °C… +60 °C

Permissible operating voltage:

1.1 Un – 8 h/day

1.15 Un – 0.5 h/day

1.2 Un – 5 min

1.3 Un – 1 min

Permissible overcurrent: 1.3 In

Housing ingress protection: IP 00

Operating position:

- vertical

- horizontal on the narrow side

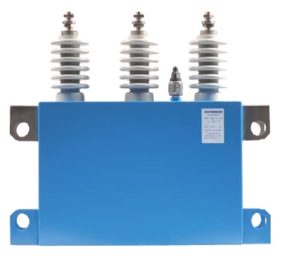

THREE-PHASE OIL CAPACITORS

Three-phase power capacitors are manufactured for use indoors and outdoors.

The capacitors are equipped with internal coil protections and discharge resistors that guarantee reduced voltage on terminals, in compliance with the standards.

The capacitor’s dielectric material is polypropylene in the form of coatings sprayed on both sides of an aluminium foil, encapsulated in a stainless-steel, powder coated housing.

GENERAL TECHNICAL PARAMETERS

Rated voltage: 1…13.0 kV

Rated power: 20…300 kVar

Frequency: 50 or 60 Hz

Active power loss: 0.07…0.15 W/kVar

Capacitance tolerance: -5% … +10%

Temperature class: -25°C… +60 °C

Permissible operating voltage:

1.10 Un – 8 h/day

1.15 Un – 0.5 h/day

1.20 Un – 5 min

1.30 Un – 1 min

THREE-PHASE DRY CAPACITORS

MSD dry capacitors are dedicated for installation in facilities with increased fire risks, such as mines, water conservation areas or potable water pump stations. They find wide application in situations, where oil-insulated capacitors are not approved for operation.

The MSD technology is based on a consistent continuation of the proven technology of “self-healing” low voltage power capacitors. It also enables eco-friendly manufacturing of MV capacitors without flammable oil fill. The actual active part of a capacitor consists of a large number of high-quality “self-healing” MKP round coils, interconnected into packages embedded in a metal housing.

A special process is used to achieve the excellent insulation (constituting a solid material) between the active part and the housing, designed and tested in accordance with rated insulation requirements.

GENERAL TECHNICAL PARAMETERS

Rated voltage: 3.3…12 kV

Rated power: 50…535 kVar

Frequency: 50 or 60 Hz

Active power loss: 0.25 W/kVar

Capacitance tolerance: -5…+5%

Temperature class: -40/D

Permissible operating voltage:

1.1 Un – 12 h/day

1.15 Un – 0.5 h/day

1.2 Un – 5 min (200x)

1.3 Un – 1 min (200x)

Permissible overcurrent: 1.3 In

Service life: 100 000 h

Compliance with standards: IEC-871, VDE-EN 61071, PN-EN 871-1

REACTORS LIMITING SWITCHING CURRENTS

They are used to limit transient overcurrents that may occur when switching the capacitors into the network.

This phenomenon is especially exacerbated when a bank is switched in parallel with other, already energised capacitor banks.

Limiting reactors reduce overcurrents to value suitable to the capacitors.

Technical data:

Rated voltage: 3kV, 6kV, 10kV, 15kV, 20kV, 30kV

Current/inductances: as required

Rated frequency: 50Hz

Ingress protection: IP 00

Execution:

– indoor or outdoor

DETUNED REACTORS P=7%, P=14%

Detuned reactors should be used to protect capacitors in networks with devices that generate higher harmonics, which may experience the bank resonating with the network. Together with the capacitor capacitance they form resonant circuits, protecting the capacitors against higher harmonics.

Depending on the needs, reactors can be coreless or have a core.

Reactors with p=7% – protect capacitors from the 5th harmonic

Reactors with p=14% – protect capacitors already from the 3rd harmonic

INDUCTIVE REACTORS (CAPACITIVE REACTIVE POWER COMPENSATION)

Reactors are intended for compensating capacitive reactive power.

They are available with cores and as coreless, to be installed indoors or outdoors

MV reactors are used primarily for compensating long MV/HV cable lines, that introduce capacitive reactive power to the grid.